Introduction

In a conversation about streamlining procurement processes and improving purchasing strategies, how much are you able to contribute? To display sufficient knowledge, you must know the difference between procurement and purchasing.

This article here will throw light on the differences between procurement and purchasing, offer deeper insights into how it is used in organizations, its relevance, and much more.

What is purchasing and procurement?

The difference between procurement and purchasing may seem non-existent. After all, don’t both terms revolve around acquiring goods and services? Let us consider an example here.

Imagine a company needs to acquire software licenses to bolster its IT infrastructure. Purchasing is the act of placing an order and completing the transaction to obtain those licenses. It involves the tangible exchange of money for the desired products or services.

However, before making the purchase, there are several intricate processes that occur behind the scenes. These may involve researching potential vendors, negotiating contracts, assessing supplier performance, and developing long-term procurement strategies. This complete process of acquiring goods and services is procurement.

To make things even more clear, let us look at the definition of the terms.

Quick Read: Source-to-pay (S2P): Meaning, Process, Steps and Benefits

Definition of procurement

As a CFO, you probably understand the significance of procurement within your organization. Procurement, in its essence, refers to the strategic process of sourcing, acquiring, and managing goods, services, and resources to meet the operational needs of the company while maximizing value and mitigating risks.

Further, by implementing excellent procurement strategies, you aim to optimize costs, drive operational efficiencies, foster vendor relationships, and enhance overall competitiveness.

The process involves a comprehensive approach that spans various stages.

- The identification of requirements

- The development of specifications

- The evaluation of potential suppliers

- Engaging in negotiations to secure favorable terms and pricing

- Selecting the most suitable vendors.

- Rigorous contract management and ongoing supplier performance evaluations

Quick Read: TOP 10 Procurement Software

Definition of purchasing

Purchasing(centralized or decentralized) plays a critical role in any organization’s procurement process. It refers to the operational side responsible for executing the procurement process by acquiring goods and services needed to support the company’s day-to-day operations.

Purchasing involves the actual transactional activities associated with procuring resources. The activities involved include:

- Raising purchase orders

- Coordinating with suppliers

- Negotiating terms and conditions

- Processing invoices

- Timely delivery of goods and services.

Essentially, purchasing serves as the bridge between the organization and its suppliers.

Quick Read: 10 Best Purchasing Software

Importance of distinguishing between procurement and purchasing

In a chip manufacturing export company, purchasing and procurement play distinct yet interconnected roles. Let’s consider an example to understand why you must know the difference between procurement and purchasing.

A chip manufacturing company requires a specialized machine for the production of advanced microprocessors. The procurement department takes charge of the strategic procurement process. They conduct market research to identify potential suppliers of these machines, evaluate their capabilities, and negotiate contracts.

Then the team considers technological advancements, quality, reliability, and long-term support factors. They aim to establish favorable supplier relationships and secure the best possible terms for acquiring the required equipment.

Once the procurement process is completed, the purchasing department takes over. They are responsible for the operational aspects of obtaining the machine. This involves raising purchase orders, coordinating with the supplier regarding delivery schedules, and ensuring the machine’s timely arrival.

The purchasing team works closely with logistics and warehouse departments to facilitate the smooth transition of the machine into the manufacturing facility.

While procurement focuses on strategic decision-making and long-term supplier management, purchasing is more transactional, dealing with the day-to-day execution of procurement decisions.

Quick read: Sourcing vs Procurement: A complete Guide on Key Differences

Understanding the key differences between procurement and purchasing

| The critical difference between procurement and purchasing lies in their scope and strategic nature. Procurement is an umbrella term that covers the end-to-end process of sourcing, acquiring, and managing goods, services, and resources to meet organizational needs. Procurement takes a holistic approach, considering quality, cost optimization, risk mitigation, and long-term value creation. On the other hand, purchasing is a subset of procurement and focuses on the transactional activities of acquiring goods and services. It involves raising purchase orders, coordinating with suppliers, processing invoices, and ensuring the timely receipt of products or services. Purchasing primarily deals with the operational execution of procurement decisions and ensures the organization’s smooth flow of goods and services. |

Difference between procurement and purchasing

Here’s a quick recap of the differences between procurement and purchasing.

- Procurement is a strategic process, while purchasing is an operational function.

- Purchasing focuses on the transactional aspects of acquiring goods and services, but procurement involves sourcing, acquiring, and managing goods, services, and resources.

- The activities involved in procurement include supplier evaluation, contract negotiation, and supplier relationship management while purchasing deals with raising purchase orders, coordinating with suppliers, and processing invoices.

- The procurement cycle considers long-term value creation, cost optimization, and risk mitigation. On the other hand, purchasing ensures the smooth execution of procurement decisions and the timely receipt of products or services.

- Procurement is a comprehensive approach that aligns with the organization’s goals, while purchasing is a subset of procurement that supports the operational aspects of procurement.

Quick read: Purchase Order and Invoices: Definition and Differences

Procurement Detailed Explanation

Overview

Procurement is a strategic process that involves sourcing, acquiring, and managing goods, services, and resources to meet organizational needs. At a deeper level, it goes beyond just the transactions, as it focuses on long-term value creation, cost optimization, and risk mitigation.

Roles and responsibilities in procurement

For success in procurement activities, several roles and responsibilities must work in sync. Let us look at the key stakeholders involved in this process.

- Procurement Manager: Procurement professionals oversee the entire procurement function, develop strategies, and ensure compliance.

- Sourcing Specialists: Generally, this role requires them to conduct market research, identify potential suppliers, and evaluate their capabilities.

- Contract Negotiators: Negotiation specialists engage in negotiations with suppliers to secure favorable terms and conditions.

- Supplier Relationship Managers: Here, the attempt is to foster strong relationships with suppliers, monitor performance through pre-decided procurement KPIs, and address issues.

- Quality Control Analysts: They ensure the purchased goods and services meet your organization’s quality standards and specifications.

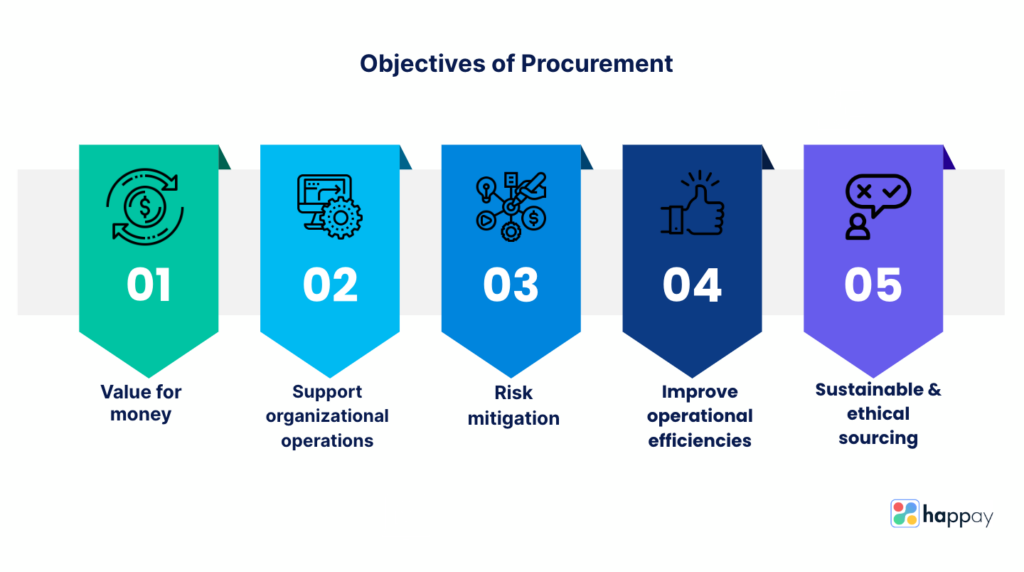

Objectives of procurement

The objectives of procurement include

- Optimizing cost and achieving value for money.

- Support organizational operations by ensuring the regular availability of goods and services

- Mitigate risks by selecting reliable suppliers and establishing robust contractual agreements.

- Improving operational efficiency through effective supplier management and collaboration.

- Promoting sustainability and ethical sourcing practices.

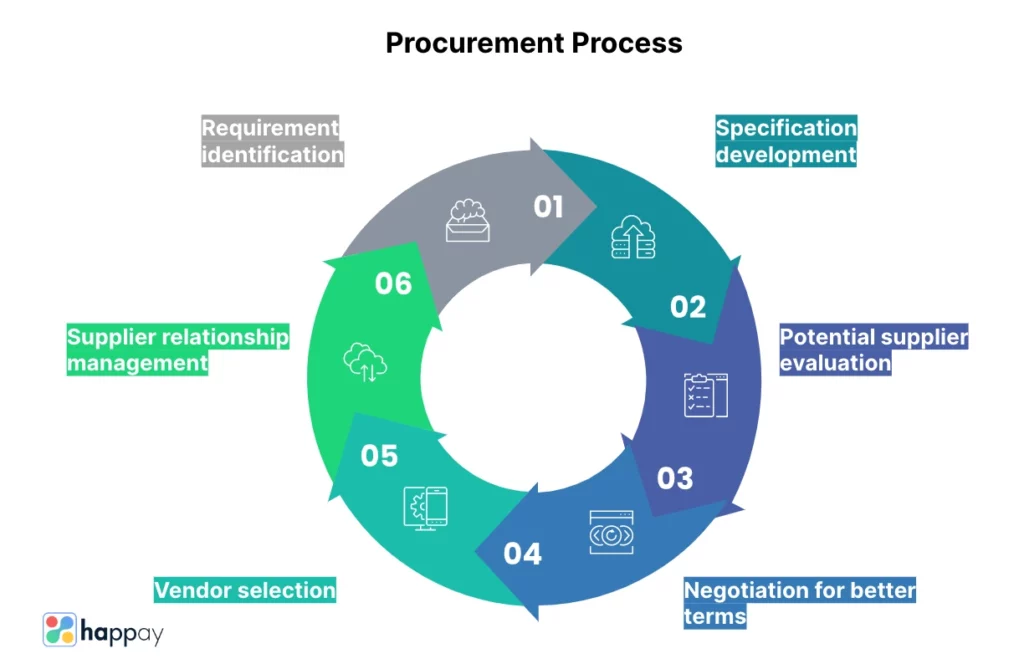

Steps in the procurement process

The procurement process typically involves the following steps.

- Identification of business needs: Determine the goods, services, or resources required to meet organizational needs.

- Identify suppliers: Look for, research, and identify potential suppliers for your organization.

- Supplier Evaluation: Assess suppliers based on quality, reliability, pricing, and capabilities.

- Negotiation: Engage in negotiations to secure favorable terms, pricing, and contractual agreements.

- Contract Finalization: Finalize and sign contracts with selected suppliers.

- Order Placement: Raise purchase requests with agreed specifications, quantities, and delivery timelines.

- Receipt and Inspection: Receive goods or services, and inspect them for quality and conformity to specifications.

- Invoice Processing and Payment: Process supplier invoices and ensure timely payment.

Quick Read: Strategic Sourcing: What is it, Importance, Objectives & Steps

Example of Procurement

In a textile company, procurement plays a crucial role in sourcing raw materials, machinery, and services. For example, the procurement team may identify suppliers for high-quality cotton fibers to be used in fabric production.

They evaluate potential suppliers based on fiber quality, consistency, sustainability practices, and pricing. Negotiations are conducted to secure favorable payment terms and delivery terms. Once contracts are finalized, purchase orders are raised, and the cotton fibers are delivered to the manufacturing facility.

The procurement team ensures the quality of the received materials, processes supplier invoices, and facilitates timely payments.

Purchasing

An overview of the function

Purchasing is an operational function within the broader scope of procurement. The transactional activities in acquiring goods and services required by an organization are a part of this function. The goal here is to ensure the smooth execution of procurement decisions, including raising purchase orders, coordinating with suppliers, and managing the delivery of products or services.

Roles and responsibilities in purchasing

Success in this functionality requires various roles and responsibilities to contribute effectively. Key stakeholders involved are

- Purchasing Manager: They oversee the entire purchasing process, coordinating with internal stakeholders, and ensuring timely procurement.

- Buyer: Here, the dedicated buyer identifies the goods or services needed, raises purchase orders, and communicates with suppliers regarding specifications and delivery requirements.

- Vendor Management: A vendor manager manages relationships with suppliers and other third-party vendors, monitors their performance, and addresses any issues or concerns.

- Inventory Control: The main responsibility is the maintenance of inventory levels, monitoring stock availability, and ensuring an adequate supply of materials.

- Accounts Payable: This department processes supplier invoices, verifies their accuracy, and facilitates timely payments.

Quick Read: 9 Best Vendor Payment Management Software

Objectives of purchasing

The objectives of purchasing include:

- Ensuring the timely availability of goods and services to support operational needs.

- Obtaining quality products or services that meet the specified requirements.

- Achieving cost-efficiency through effective negotiation and securing competitive pricing.

- Managing supplier relationships and fostering collaboration for long-term partnerships.

- Streamlining the process to enhance operational efficiency.

Quick Read: What Is Purchase Order Automation and How to Do the PO Process?

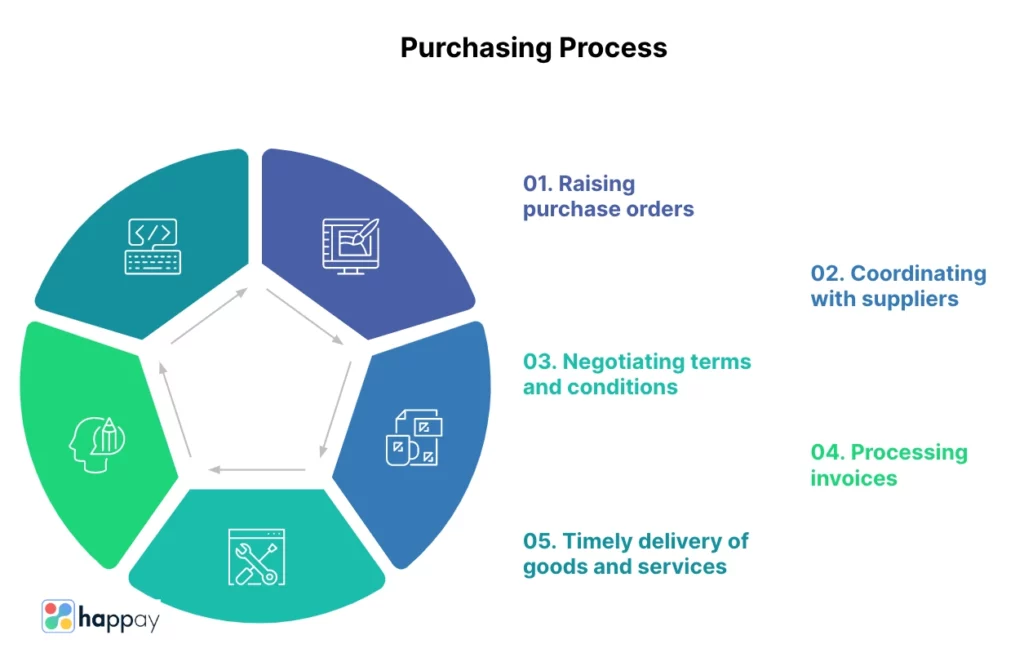

Steps in the purchasing process

The purchasing process typically involves the following steps.

- Identify Needs: Understand and determine the goods or services required based on organizational needs.

- Requisition: Generate a purchase requisition to begin the purchasing process.

- Supplier Identification: Identify potential suppliers who meet the requirements.

- Right price and Terms Negotiation: Negotiate to secure favorable pricing, terms, and conditions.

- Purchase Order Creation: Initiate a purchase order with accurate details such as quantity, specifications, and delivery date.

- Order Confirmation: Receive confirmation from the supplier regarding acceptance of the purchase order.

- Delivery and Receipt: Coordinate with the supplier to deliver goods or services and ensure accurate receipt of the same.

- Invoice Processing and Payment: Verify supplier invoices, process them for payment, and facilitate timely settlement.

Quick Read: 12 Best Invoicing Software

Example of Purchasing

In the previous textile company example, the purchasing function ensures the smooth execution of procurement decisions made by the team. Once the procurement team has identified the preferred suppliers of cotton fibers, the purchasing department raises purchase orders specifying the quantity and delivery requirements.

They coordinate with the suppliers to ensure timely delivery of the fibers to the manufacturing facility. Upon receipt, the purchasing team verifies the quality and quantity of the materials and processes the supplier invoices for payment.

Effective inventory management is also maintained to avoid stockouts and ensure the availability of materials for uninterrupted production.

Quick read: What Is Spend Analytics in Procurement?

Procurement vs Purchasing: Understanding the Differences and Similarities

Differences

Features |

Procurement |

Purchasing |

|

Scope |

Strategic and comprehensive |

Operational and transactional |

|

Focus |

Long-term value creation, cost optimization, risk mitigation |

Timely acquisition and delivery of goods/services |

|

Decision-making |

Strategic decision-making processes |

Operational execution of procurement decisions |

|

Responsibilities |

Supplier evaluation, contract negotiation, supplier relationship management |

Raising purchase orders, coordinating with suppliers |

|

Supplier Engagement |

Supplier identification, selection, and relationship management |

Coordinating delivery schedules, receipt of goods/services |

|

Involvement in Strategy |

Integral part of corporate strategy planning and decision-making |

Implementation of procurement strategies and decisions |

|

Timeframe |

Long-term and ongoing |

Short-term and immediate |

|

Key Focus Areas |

Supplier selection, negotiation, risk management |

Order placement, supplier coordination, invoice processing |

|

Performance Measurement |

Supplier performance evaluation, value generation assessment |

Efficiency in order processing and delivery |

Similarities

Now that we have discussed the differences between procurement and purchasing extensively, could there be similarities between the two functions?

Similarities |

Procurement and Purchasing |

|

Objective |

Acquiring goods, services, and resources to meet the organization’s internal needs |

|

Supplier Engagement |

Engaging with suppliers and negotiating contracts |

|

Supply Chain Focus |

Contributing to the overall supply chain |

|

Cost Consideration |

Striving for cost-efficiency and budget management |

|

Quality Assurance |

Ensuring the quality of acquired goods and services |

|

Supplier Management |

Establishing and maintaining relationships with suppliers |

|

Communication |

Effective communication with suppliers and internal stakeholders |

|

Compliance |

Adherence to legal and ethical standards |

|

Documentation |

Managing necessary documentation and record-keeping |

|

Collaboration |

Collaborating with internal stakeholders for successful procurement |

|

Evaluation |

Assessing and evaluating potential suppliers |

Quick read: Vendor Management System (VMS): Benefits, Features & TOP Systems

When to use Procurement over purchasing?

What should enterprises pick in procurement vs purchasing? Generally, this is based on their specific needs and strategic objectives. The decision to procure or purchase depends on the organization’s scale, complexity, and long-term goals.

Enterprises should choose procurement when?

- They require a holistic approach that involves strategic decision-making, supplier evaluation, and long-term value creation. So, the goal is strategic decision-making.

- They aim to establish and nurture strong relationships with suppliers to ensure reliable and sustainable partnerships. Here, they are seeking to improve supplier relationships.

- They must mitigate risks by carefully selecting suppliers, negotiating contracts, and managing supplier performance. The focus here is risk mitigation.

- They seek to optimize costs through strategic sourcing, negotiation, and value generation. So, here the aim is cost optimization.

Enterprises may choose purchasing when?

- The goal is improved operational execution. So, in this case, they need to focus on the operational aspects of acquiring goods and services, such as raising purchase orders and coordinating with suppliers.

- The organization is focused on immediate requirements. They require a quick and efficient process to fulfill those immediate needs and ensure timely delivery of goods or services.

- The enterprise is concerned about transactional efficiencies. Here, they aim for streamlined transactional activities, including invoice processing, order placement, and receipt verification.

- The perspective is short-term goals. Here, the organizations prioritize immediate procurement needs without extensive supplier evaluation or long-term strategic considerations.

Ultimately, the choice between procurement and purchasing depends on your priorities, resources, and strategic involvement required to effectively meet their objectives.

Quick Read: TOP 6 Enterprise Payment Software

How can businesses embrace automation in procurement and purchasing?

Automation has pretty much become a norm all around us. So, to gain a competitive advantage and drive efficiencies in procurement and purchasing, enterprises must embrace automation. Organizations can streamline their procurement and purchasing processes by leveraging automation tools and technologies, resulting in significant benefits.

For instance, automated purchase order generation and electronic invoicing(e-invoice) can eliminate manual paperwork. It leads to reduced processing time, enabling faster order placement and payment processing. Similarly, automated inventory management systems can track stock levels in real-time, triggering automatic reordering when inventory falls below a certain threshold. This process prevents stockouts and ensures seamless production.

Automation can also significantly contribute to better data accuracy. It eliminates manual data entry errors and reduces the risk of incorrect orders or duplicate payments. Moreover, automation provides visibility into spending patterns and supplier performance, enabling businesses to identify cost-saving opportunities and negotiate better terms with suppliers.

Overall, embracing automation in procurement and purchasing empowers businesses to optimize costs, improve decision-making, and enhance productivity. You can focus on strategizing to drive growth and innovation.

Quick read: Difference Between Invoice and Bill: A Complete Guide

Key Considerations for Implementing Automation

Before implementing automation across your organization, here are a few key considerations.

- Process Evaluation: Assess existing processes for automation potential.

- System Selection: Choose a suitable automation system.

- Data Integration: Ensure seamless integration with other systems.

- Workflow Automation: Streamline tasks like order generation and invoice processing.

- Supplier Collaboration: Facilitate efficient communication with suppliers.

- Data Security: Implement robust security measures.

- Training and Change Management: Provide user training and manage the transition.

- Continuous Improvement: Monitor and enhance automation over time.

- Regulatory Compliance: Ensure adherence to relevant regulations.

- Performance Measurement: Track key metrics to evaluate effectiveness.

Automated procurement tools and software

Several tools and procurement software can be used to automate your procurement processes. Procurement software not only plays a big role in digitizing but can help in easing the integration of the procure-to-pay process. Further, such software can help your organization become proactive as against reactive when it comes to tackling issues in procurement. Let us look at some of the best procurement tools.

- Precoro

- SAP Ariba Procurement

- Tipalti

- Tradeshift

- Jaggaer

- Procurify

- Basware

- Quartzy

- Proactis

- Logility

Quick Read: TOP 10 Procure-to-Pay Software Solutions

Conclusion

Understanding the difference between procurement and purchasing is crucial for businesses to manage their supply chain and optimize their procurement strategies effectively. By recognizing the nuances between the two, businesses can allocate resources appropriately, implement tailored processes, and make informed decisions. Finally, understanding these distinctions helps organizations leverage the right tools and technologies for each function, improving efficiency, reducing costs, and ensuring compliance.

FAQs

Yes, purchasing is sometimes referred to as a subset or component of the broader procurement function. While these terms are very often used interchangeably, it’s important to note that procurement has a wider scope. It includes strategic supplier management, sourcing, negotiation, and contract management. On the other hand, purchasing specifically refers to the transactional aspect of acquiring goods or services.

Let us understand the scope of the terms using an example. In a manufacturing company, procurement would involve strategic decisions such as identifying and evaluating suppliers, negotiating contracts, and managing supplier relationships to ensure a steady supply of raw materials.

On the other hand, purchasing would focus on the day-to-day activities of raising purchase orders, processing invoices, and coordinating with suppliers for timely delivery.

The main difference between procurement and purchasing sourcing lies in their focus and scope. Procurement sourcing involves strategic activities such as identifying potential suppliers, evaluating their capabilities, negotiating contracts, and managing supplier relationships. On the other hand, purchasing sourcing is more transactional and operational, involving the actual selection of suppliers and obtaining the required goods or services. While procurement sourcing is a broader strategic process, purchasing sourcing is a subset that specifically deals with the sourcing activities related to purchasing goods or services.

Here are the seven stages of procurement and purchasing.

1. Need Identification: Identifying the goods, services, or resources required.

2. Supplier Identification: Identifying potential suppliers.

3. Supplier Evaluation and Selection: Assessing and selecting the most suitable suppliers.

4. Negotiation: Negotiating terms, pricing, and contracts with chosen suppliers.

5. Purchase Order: Creating and issuing a purchase order to initiate the transaction.

6. Receipt and Inspection: Receiving the goods or services and inspecting them for quality and accuracy.

7. Payment and Record-Keeping: Processing payments to suppliers and maintaining proper documentation.

Procurement and purchasing can collaborate closely to achieve efficient and effective supply chain management.

While procurement focuses on strategic supplier relationships, sourcing, and contract management, purchasing handles the transactional aspects of acquiring goods or services. Collaboration between the two functions ensures the alignment of strategic goals with operational execution.

Procurement provides insights into supplier capabilities and market trends, enabling purchasing to make informed decisions. Purchasing communicates requirements and specifications to procurement for supplier evaluation.

Procurement and purchasing can optimize costs, ensure timely delivery, maintain quality standards, and drive overall supply chain performance by working together.

In the future, we can expect several trends in the automation of procurement and purchasing. Artificial intelligence (AI) and machine learning will significantly contribute to automating repetitive tasks, improving spend analytics, and enhancing decision-making processes.

Robotic Process Automation (RPA) will continue streamlining manual processes, reducing errors, and increasing efficiency. Advanced analytics and data-driven insights will enable proactive supplier management and risk mitigation.

Integrating emerging technologies such as the Internet of Things (IoT) and blockchain will enhance supply chain transparency and traceability. Additionally, cloud-based procurement solutions will provide scalability, flexibility, and accessibility. Overall, the future of automation in procurement and purchasing holds immense potential to revolutionize operations, optimize costs, and drive strategic value for organizations.